High-Quality Methods for Adding Capacitors In Series from Top Manufacturers

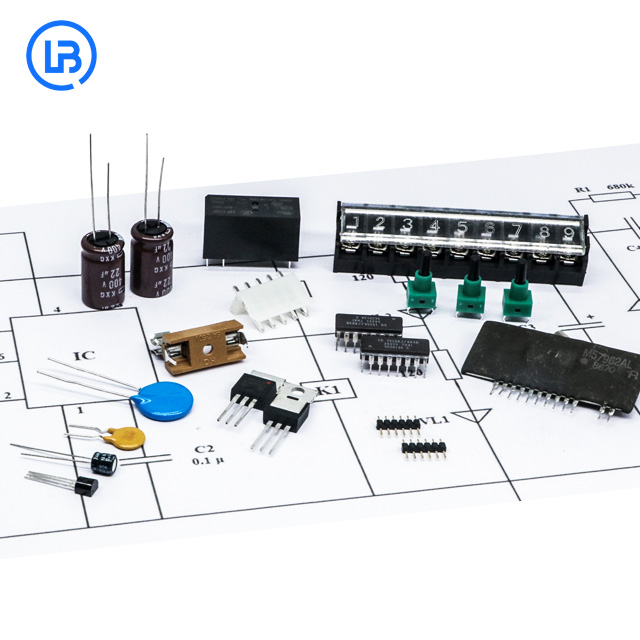

When considering adding capacitors in series, I always look for high-quality components that can deliver efficient performance. Capacitors in series are essential for increasing voltage ratings and tailoring capacitance values to meet specific circuit needs. I understand that selecting the right manufacturer is vital for ensuring reliability and durability in application. By opting for high-quality capacitors from trusted manufacturers, we can minimize risks of failure and enhance overall system stability. Each capacitor is designed with precision, ensuring optimal functionality in various settings. Whether you’re working on consumer electronics or industrial applications, our capacitors offer superior performance that meets rigorous standards. By working with reputable suppliers, I’ve found that reliability in delivery and product quality go hand in hand. So when you're ready to enhance your electrical designs, consider adding capacitors in series from a manufacturer that prioritizes excellence and innovation. Let's boost your projects together with components that stand the test of time!

Adding Capacitors In Series Winning in 2025 Custom Solutions,

As we look ahead to 2025, the demand for custom solutions in electronics continues to rise, particularly in the realm of capacitors. Understanding the advantages of adding capacitors in series is essential for engineers and procurement professionals seeking to optimize their designs. This practice not only increases the overall voltage rating of the capacitor bank but also allows for improved capacitance values tailored to specific applications. By combining capacitors in series, organizations can enhance reliability while reducing size and weight—key factors in today's competitive market. Capacitors play a crucial role in smoothing signals and providing necessary energy storage, making their selection and arrangement critically important. The ability to design custom capacitor solutions that meet unique specifications can significantly impact performance across various applications, from consumer electronics to industrial machinery. As manufacturers tailor these components for specific requirements, they must also consider aspects such as temperature stability and dielectric flexibility, ensuring longevity and efficiency in diverse environments. Looking towards the future, companies that embrace innovative capacitor configurations will be at a distinct advantage. The global push for sustainable and efficient technology opens up opportunities for collaborations in developing high-performance capacitor solutions. By fostering partnerships based on customization and expertise, businesses can not only meet the growing demands but also set new industry standards for excellence and reliability in electronic components.

Adding Capacitors In Series Winning in 2025 Custom Solutions

| Capacitor Type | Capacitance (μF) | Voltage Rating (V) | Temperature Range (°C) | Lifespan (Hours) |

|---|---|---|---|---|

| Ceramic | 10 | 100 | -25 to 85 | 10000 |

| Electrolytic | 22 | 250 | -40 to 105 | 5000 |

| Film | 100 | 400 | -40 to 85 | 20000 |

| Tantalum | 47 | 16 | -55 to 125 | 2000 |

| Supercapacitor | 500 | 2.7 | -40 to 65 | 100000 |

Related Products

Adding Capacitors In Series Market Leader From Concept to Delivery

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

WhatsApp

-

Top