Blown Capacitor Solutions for OEM Manufacturers: Expert Insights & Support

When dealing with electronic components, I understand the frustration of finding reliable solutions for blown capacitors. We specialize in providing OEM-grade capacitors that meet the strict standards set by top manufacturers. Our blown capacitors are expertly crafted to ensure longevity and optimal performance in your devices. I’ve seen firsthand how critical it is to choose the right capacitor for your applications, and that’s why I’m proud to offer products that have undergone rigorous testing. Whether you’re in need of replacements or bulk orders for production, we are committed to supporting your business with high-quality components. Our team is always here to help you navigate through your selections, making sure you get exactly what you need to keep your operations running smoothly. Don’t let blown capacitors slow you down; let’s work together to keep your projects on track.

Blown Capacitor Industry Giant Where Innovation Meets 2025

In the realm of electronics, the blown capacitor industry stands as a pivotal player, driving innovation and technological advancement. As we look towards 2025, the intersection of cutting-edge development and reliable manufacturing practices becomes increasingly significant. Companies that prioritize research and development while maintaining strict quality control are poised to lead the market, setting new standards for performance and longevity. The demand for high-quality blown capacitors is on the rise, particularly in sectors such as renewable energy, automotive electronics, and telecommunications, where reliability and efficiency are paramount. As global procurement continues to evolve, buyers are seeking partners who not only provide superior products but also embrace sustainability and eco-friendly practices. The industry is adapting to these expectations by incorporating advanced materials and processes that minimize waste and energy consumption. By focusing on innovative solutions, companies are enhancing product performance while reducing their environmental footprint, making them more attractive to conscientious buyers. This commitment to sustainability, coupled with a track record of reliability, positions leaders in the blown capacitor industry to foster lasting partnerships with clients around the world. Looking ahead to 2025, the emphasis on innovation is set to reshape the competitive landscape of the blown capacitor market. Organizations that leverage new technologies, such as smart manufacturing and automated quality assurance processes, will drive efficiency and responsiveness to market demands. The future of electrification hinges on collaboration between manufacturers and procurement specialists, ensuring that the best components are available for next-generation applications. By staying ahead of the curve in both technology and sustainability, the blown capacitor industry is set to not only meet but exceed the expectations of an increasingly discerning global market.

Blown Capacitor Industry Giant: Where Innovation Meets 2025

| Dimension | Value |

|---|---|

| Global Market Size (2025) | $12 Billion |

| Annual Growth Rate (CAGR) | 5.6% |

| Key Innovations | High-Temperature Capacitors, Eco-Friendly Materials |

| Leading Application Sectors | Consumer Electronics, Automotive, Industrial |

| Emerging Markets | Asia-Pacific, Latin America |

| Sustainability Initiatives | Recycling Programs, Energy-Efficient Production |

| Investment in R&D | $500 Million |

| Key Players in the Market | Major Companies in Electronics Manufacturing |

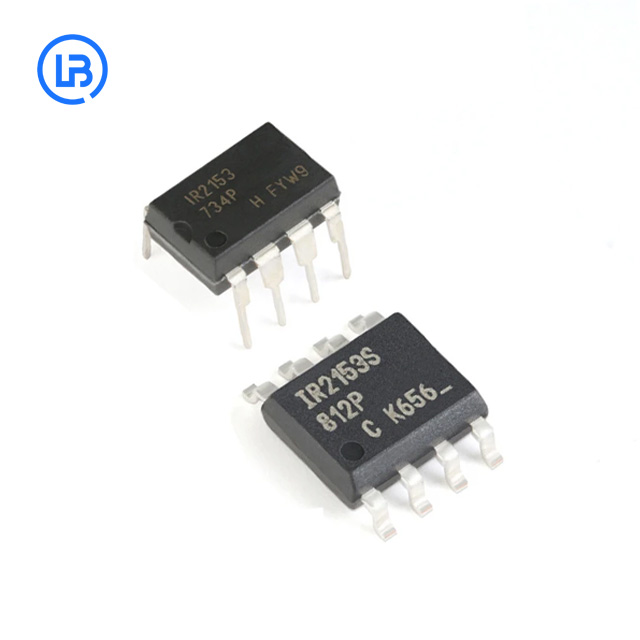

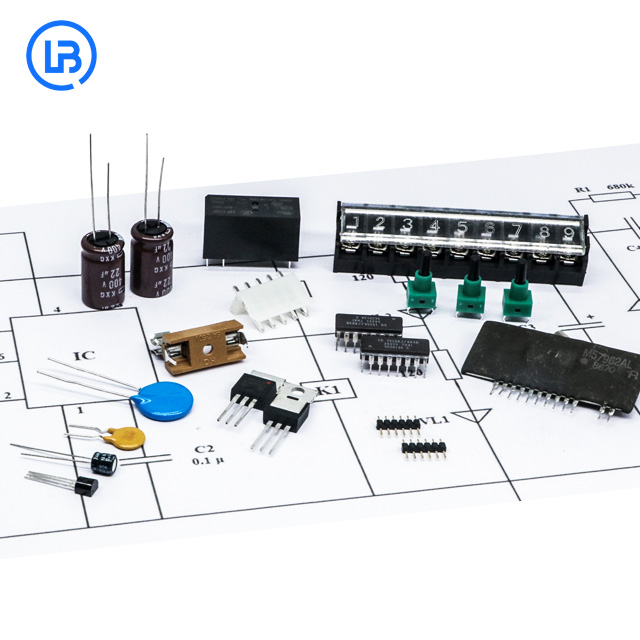

Related Products

Blown Capacitor More Than a Supplier - A Partner From Concept to Delivery

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

WhatsApp

-

Top