Capacitor Dielectric Insights for OEM Manufacturers and Buyers

When I think about the importance of high-quality capacitors in electronic devices, capacitance and dielectric materials come to mind. Capacitor dielectrics play a crucial role in determining performance and reliability, especially for OEM applications. As a manufacturer, I understand the challenges you face when sourcing components that meet specific criteria. Choose capacitors with superior dielectric materials to ensure optimal efficiency and longevity in your products. Our offerings are tailored for manufacturers who prioritize durability and functionality, allowing you to meet rigorous industry standards. I believe that our significant experience and commitment to quality make us a trusted partner for your business. Whether you’re looking for customization options or bulk orders, I’m here to assist you in finding the perfect capacitor dielectric solution for your project needs. Let’s collaborate to elevate the capabilities of your electrical devices and meet your OEM demands effectively.

Capacitor Dielectric Dominates Custom Solutions,

In the ever-evolving world of electronics, the choice of dielectric materials for capacitors plays a pivotal role in determining the performance, reliability, and efficiency of electronic devices. With various applications ranging from consumer electronics to industrial machinery, the demand for tailored capacitor solutions that meet specific requirements is on the rise. Custom capacitor designs, especially those utilizing advanced dielectric materials, enable manufacturers to optimize performance characteristics such as capacitance stability, temperature tolerance, and frequency response. As global procurement trends shift towards more specialized and high-performance components, understanding the impact of dielectric materials becomes crucial for businesses aiming to enhance their product offerings. By integrating cutting-edge technologies and materials in capacitor manufacturing, companies can provide bespoke solutions that cater to diverse industry needs. This approach not only improves product quality but also fosters innovation, allowing businesses to stay competitive in a crowded market. Investing in custom capacitor solutions that leverage superior dielectric properties opens new avenues for companies to address challenges such as size constraints, energy efficiency, and overall reliability. As the electronics landscape continues to advance, forging partnerships with manufacturers who prioritize innovation in dielectric materials will be essential for organizations seeking to thrive in a dynamic global marketplace.

Capacitor Dielectric Dominates Custom Solutions

| Dielectric Material | Dielectric Constant (εr) | Temperature Coefficient (ppm/°C) | Applications | Advantages |

|---|---|---|---|---|

| Ceramic | 1000-5000 | -15 to +100 | Filters, RF applications | High stability, wide temperature range |

| Tantalum | 25-400 | +10 to +90 | Medical devices, automotive | Compact size, high capacitance |

| Polymer | 3-50 | -20 to +60 | Consumer electronics, power supplies | Low weight, flexibility |

| Glass | 5-50 | -10 to +50 | High-frequency circuits | Excellent thermal stability |

| Film | 2-10 | -15 to +50 | Audio equipment, power circuits | Low leakage, high insulation |

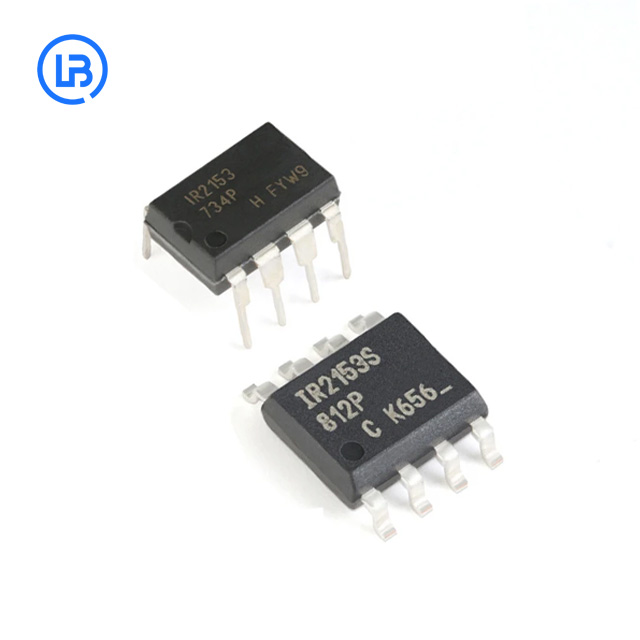

Related Products

Capacitor Dielectric Where Innovation Meets 2025 Supplies the World\u2019s Top Brands

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

WhatsApp

-

Top