High-Quality Capacitor Checking: Your Guide to Top Manufacturers

When I’m checking a capacitor, I always prioritize high-quality products that I can trust. I've found that using capacitors from reputable manufacturers makes a significant difference in performance and durability. Their products not only meet industry standards but also ensure reliability in various applications. In my experience, high-quality capacitors lead to fewer failures and improved efficiency, which is crucial for maintaining optimal operations. I appreciate that these manufacturers often provide detailed specifications, so I know exactly what I’m getting. Whether I’m sourcing for a new project or replacing components, knowing I have dependable capacitors gives me peace of mind. For anyone serious about maintaining quality in their operations, I highly recommend investing in well-made capacitors. You’ll notice the difference in performance and longevity. Let’s ensure our systems run smoothly and efficiently with the best capacitors available in the market!

Checking A Capacitor Stands Out Ahead of the Curve

In today's fast-paced technological landscape, the demand for high-performance electronic components is more pronounced than ever. One critical component that plays a vital role in various applications is capacitors. As the industry evolves, it is crucial to prioritize not only the performance of these components but also their reliability and longevity. Checking a capacitor's specifications and performance metrics becomes essential to ensure that it stands out ahead of the curve, meeting the ever-increasing expectations of global procurement buyers. Capacitors are pivotal in energy storage solutions, signal processing, and power conditioning. With advancements in technology, capacitors must now accommodate high-frequency applications and extreme environmental conditions. A manufacturer that focuses on quality assurance and innovation can provide products that exceed standard performance benchmarks, thus appealing to discerning procurement professionals. Engineers and buyers worldwide are constantly looking for components that not only fulfill current requirements but also anticipate future needs, integrating seamlessly into more complex systems. Furthermore, as sustainability becomes a priority in electronic manufacturing, capacitors that demonstrate energy efficiency and a reduced environmental impact are gaining traction. Proactive checks and innovations in capacitor design can lead to a more sustainable production process, aligning with global efforts to minimize waste and enhance energy conservation. This focus on quality, reliability, and sustainability positions a forward-thinking manufacturer at the forefront of the industry, making it the preferred choice for global procurement buyers seeking to stay ahead in a competitive marketplace.

Checking A Capacitor Stands Out Ahead of the Curve

| Capacitor Type | Capacitance (µF) | Voltage Rating (V) | ESR (Ω) | Temperature Range (°C) |

|---|---|---|---|---|

| Electrolytic | 100 | 50 | 0.15 | -40 to 85 |

| Ceramic | 10 | 250 | 0.01 | -55 to 125 |

| Tantalum | 47 | 25 | 0.12 | -55 to 125 |

| Film | 1 | 400 | 0.05 | -40 to 70 |

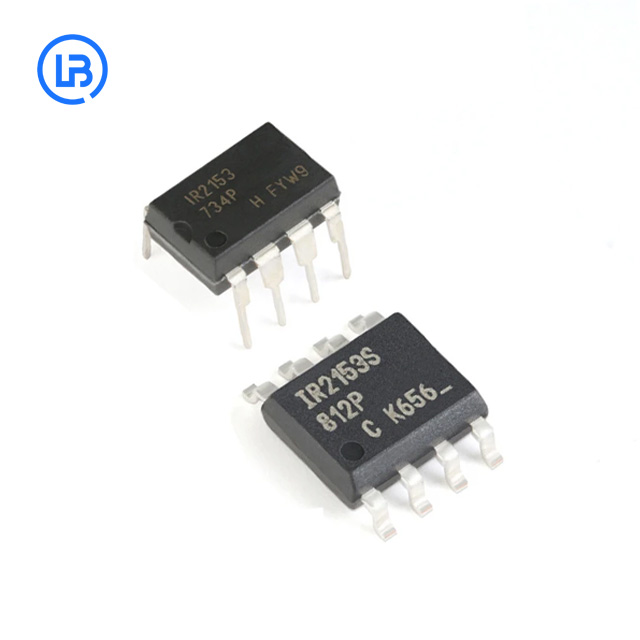

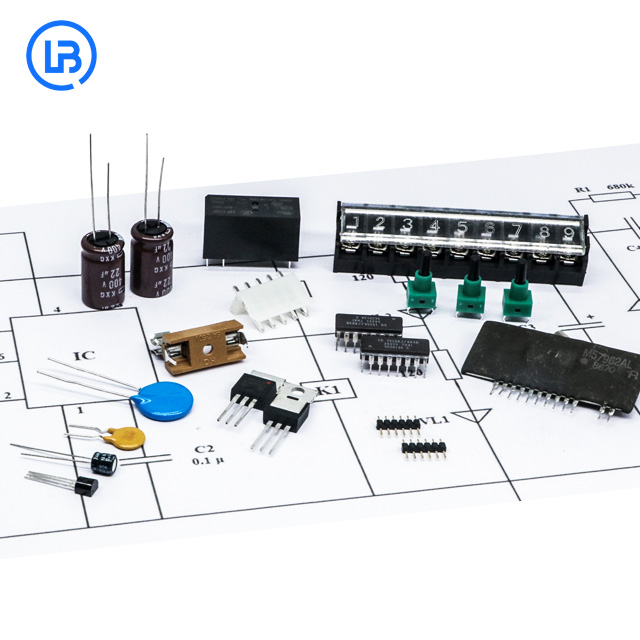

Related Products

Checking A Capacitor Factory Sets the Industry Standard

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

WhatsApp

-

Top