High-Quality Electronic PCBs from Leading Manufacturer for Your Needs

As a B2B purchaser, I understand the importance of finding reliable, high-quality electronic PCBs that meet our specific needs. That's why I prioritize manufacturers who specialize in offering tailored solutions. The electronic PCBs we provide are designed with precision and durability in mind, ensuring they perform consistently in various applications. In my experience, working with a trusted manufacturer means I can expect not only top-notch products but also excellent support throughout the procurement process. Each PCB is crafted using the latest technologies and quality materials, guaranteeing that they withstand rigorous conditions. When I choose to partner with an established manufacturer, I know I’m investing in quality and reliability, ultimately benefiting my projects. I’ve seen first-hand how high-quality electronic PCBs can lead to greater efficiency and lower failure rates. Let’s elevate our businesses together with superior products tailored to our requirements.

Electronic Pcbs For the Current Year Winning in 2025

As we look towards 2025, the demand for electronic PCBs (Printed Circuit Boards) continues to evolve, driven by advancements in technology and the increasing need for high-performance electronics in various sectors. From consumer electronics to medical devices and automotive applications, PCBs play a crucial role in ensuring the functionality and reliability of modern devices. With the growing complexity of electronic designs, the focus on high-quality, durable, and cost-effective PCB solutions becomes essential for global procurement specialists. To remain competitive, businesses must prioritize partnerships with manufacturers that offer cutting-edge technology and expertise in PCB design and production. This year, innovations such as flexible PCBs, high-density interconnects, and environmentally friendly manufacturing processes are gaining traction. As industries become more interconnected, the ability to source PCBs that not only meet regulatory standards but also offer enhanced performance and innovation will be a key differentiator. By identifying suppliers that emphasize research and development, procurement teams can ensure they are equipped to meet upcoming challenges and leverage new opportunities. In conclusion, as we approach 2025, the landscape of electronic PCBs is marked by rapid change and opportunity. Global buyers need to be proactive in seeking out manufacturers that can offer both advanced technology and personalized service. By staying ahead of the trends and understanding the specific needs of their industries, procurement teams can secure the electronic components necessary for future innovation and growth, establishing a competitive edge in their respective markets.

Electronic PCBs For the Current Year Winning in 2025

| Category | Application | Material | Thickness (mm) | Layer Count | Heat Resistance (°C) | Year of Winning |

|---|---|---|---|---|---|---|

| Consumer Electronics | Smartphones | FR-4 | 1.6 | 4 | 130 | 2025 |

| Automotive | Infotainment Systems | High-Tg FR-4 | 1.6 | 6 | 140 | 2025 |

| Medical Devices | Diagnostic Equipment | Polyimide | 0.8 | 2 | 200 | 2025 |

| Telecommunications | Base Stations | FR-4 | 1.6 | 8 | 150 | 2025 |

| Aerospace | Navigation Systems | Ceramic | 1.0 | 10 | 250 | 2025 |

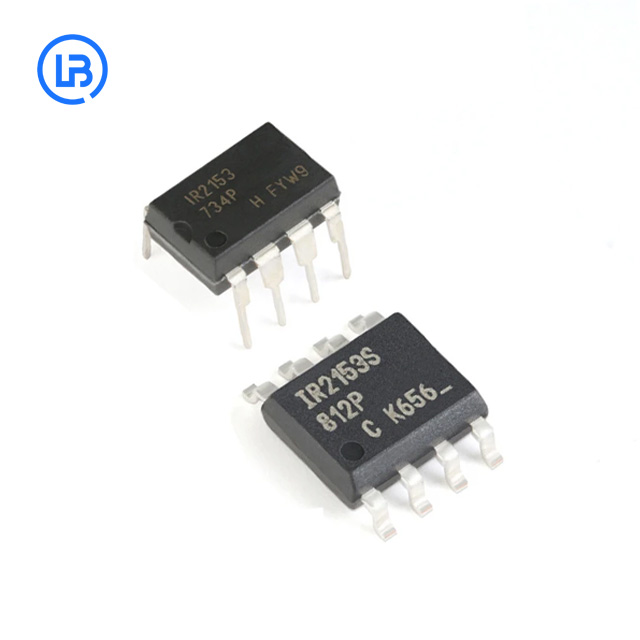

Related Products

Electronic Pcbs Where Innovation Meets 2025 Service Backed by Expertise

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

WhatsApp

-

Top