High-Quality Industrial PCB Manufacturer for Reliable Solutions

When I search for high-quality industrial PCBs, I prioritize reliability and durability, key aspects that our products excel in. Our industrial PCBs are crafted meticulously, ensuring they meet the rigorous demands of various industries. As a manufacturer, we focus on using premium materials and cutting-edge technology, which leads to superior performance and longevity in every board we create. I understand that B2B purchasers like myself need timely solutions, and that’s why we offer customizable options tailored to specific requirements. Our commitment to quality means you won't have to worry about failures or delays in your operations. With our industrial PCBs, you can expect impeccable craftsmanship that keeps your projects running smoothly. Let's elevate your operations together with our high-quality solutions, designed to meet your business needs effectively. Trust me, our products won’t just meet your standards—they’ll exceed them.

Industrial Pcb Ahead of the Curve Where Innovation Meets 2025

As we look ahead to 2025, the industrial PCB sector is poised for transformative advancements. With the increasing demand for high-performance electronic products, the integration of innovative technology stands at the forefront, ensuring that manufacturers can meet evolving market needs. Enhanced automation, miniaturization, and sustainability are shaping the future of PCBs, making them more efficient while reducing environmental impact. The compelling intersection of these trends positions businesses to stay ahead in a competitive landscape. The innovation-driven approaches in industrial PCB design and manufacturing enable customized solutions that cater to a variety of industries, from automotive to telecommunications. As smart devices proliferate, the necessity for robust, flexible, and reliable PCBs becomes vital. The incorporation of advanced materials and techniques—such as flexible and rigid-flex designs—facilitate the creation of lightweight and compact electronic systems that are crucial for modern applications. Global procurement professionals should consider the strategic advantages of partnering with companies that prioritize innovation in their PCB offerings. By investing in advanced technologies and research, organizations are not just enhancing their product lines, but also paving the way for sustainable growth and customer satisfaction in the rapidly evolving electronics market. This proactive approach ensures that suppliers remain integral to the supply chain as we move toward a smarter, more connected future.

Industrial PCB Ahead of the Curve: Where Innovation Meets 2025

| Parameter | Description | 2025 Goal | Current Status | Innovation Focus |

|---|---|---|---|---|

| Power Efficiency | Reduce power consumption by optimizing design | 30% reduction | 25% reduction achieved | Advanced Materials |

| Size Reduction | Miniaturization of components for smaller PCBs | 50% smaller | 30% smaller achieved | Nano-Technology |

| Environmental Compliance | Meet stringent environmental regulations | 100% compliance | 85% compliance | Sustainable Materials |

| Cost Efficiency | Lower production costs through innovation | 20% reduction | 10% reduction achieved | Automated Manufacturing |

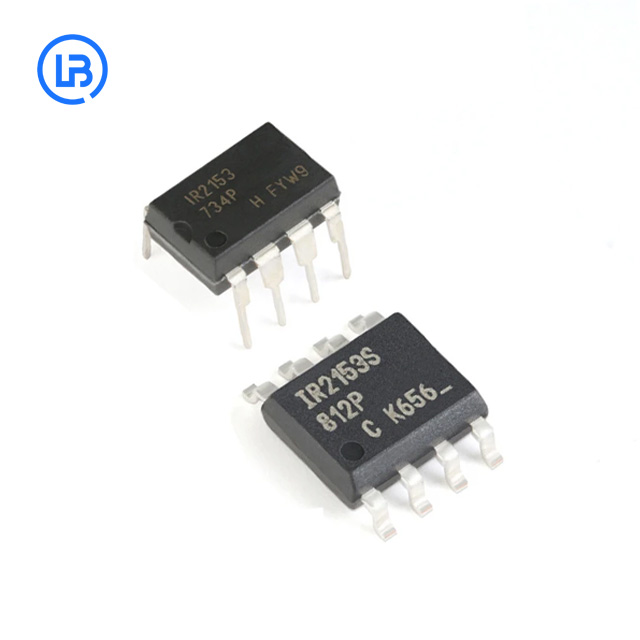

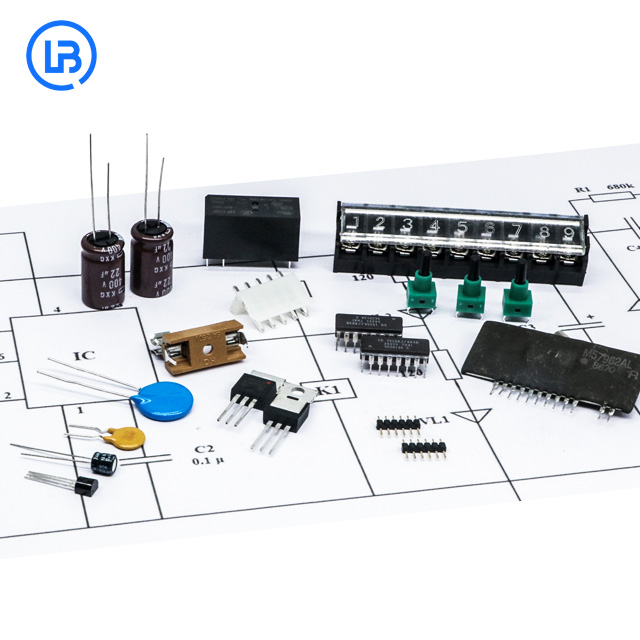

Related Products

Industrial Pcb Factory Industry Giant

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

WhatsApp

-

Top