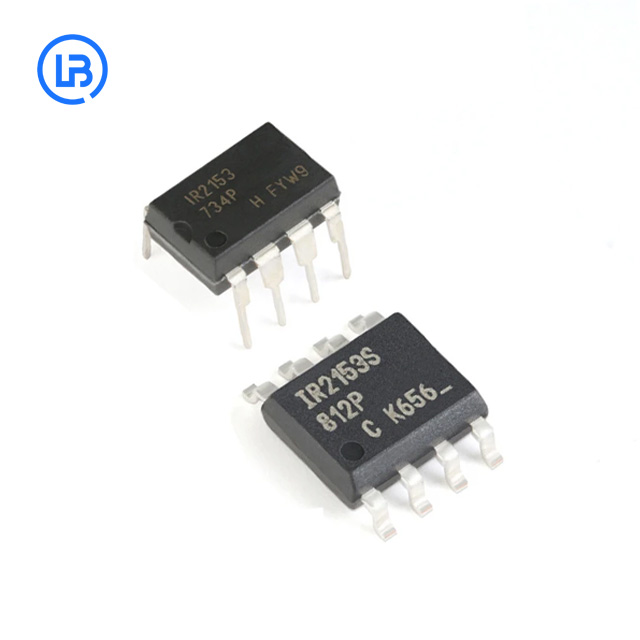

Monolithic ICs for OEMs: Top Manufacturers and Expert Insights

When it comes to enhancing your product designs, I often find that monolithic ICs are a game changer. These integrated circuits combine multiple functions into a single chip, offering remarkable efficiency and reliability. As a B2B purchaser, you'll appreciate how these components can streamline your manufacturing processes and minimize costs. Whether you’re sourcing from OEMs or working directly with manufacturers, choosing the right monolithic IC can significantly impact your product performance. I’ve seen firsthand how integrating these chips into designs leads to improved functionality, shorter development times, and greater market competitiveness. Collaborating with trusted suppliers ensures consistent quality and support, making it easier to meet your project timelines. By embracing monolithic ICs, you can elevate your offerings and stay ahead in the fast-paced tech landscape.

Monolithic Ic Service Factory-Direct Excellence

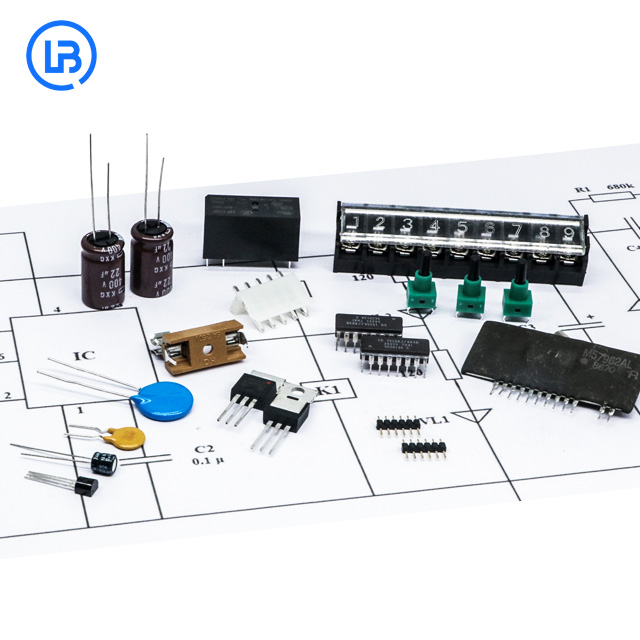

In today's fast-paced electronic market, sourcing high-quality components is essential for manufacturers aiming to stay competitive. The monolithic IC service factory model offers unparalleled efficiency and excellence, enabling businesses to streamline their supply chains while ensuring superior product standards. This approach allows for a tightly controlled production process, reducing lead times and minimizing costs associated with procurement. By leveraging advanced manufacturing techniques, companies can access a wide range of integrated circuits that cater to various applications, from consumer electronics to sophisticated industrial machinery. Sustainability and innovation are at the forefront of modern manufacturing, making it imperative for global buyers to partner with factories that prioritize these values. An effective monolithic IC service factory embraces cutting-edge technology and eco-friendly practices, allowing for a responsive and adaptive production environment. This commitment to excellence not only enhances product performance but also contributes to a sustainable future, which is increasingly important to today's environmentally conscious consumers. By choosing a factory-direct approach, global purchasers can benefit from direct communication with manufacturers, fostering transparency and collaboration. This not only enhances trust but also enables manufacturers to quickly adapt to evolving market demands. Collaborating closely with suppliers through a monolithic IC service factory ensures that businesses can meet their specific needs with customized solutions, solidifying their position in the dynamic electronics landscape.

Monolithic Ic Service Factory-Direct Excellence

| Service Type | Description | Lead Time | Customer Support |

|---|---|---|---|

| Design Services | Comprehensive design solutions for monolithic ICs | 4-6 weeks | 24/7 Technical Support |

| Manufacturing | High-volume production of ICs with precision | 8-10 weeks | Dedicated Account Manager |

| Testing & Validation | Thorough testing to ensure product reliability | 2-3 weeks | Expert Validation Team |

| Prototyping | Rapid prototyping services for quick iteration | 1-2 weeks | Project Consultation Available |

| Packaging Solutions | Custom packaging for enhanced product protection | 3-4 weeks | Packaging Support Team |

Related Products

Monolithic Ic Now Trending Your Trusted OEM Partner

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

WhatsApp

-

Top