Pcb Board Assembly for OEM Manufacturers: Quality & Precision Guaranteed

As a seasoned provider of PCB Board Assembly, I understand the complexities that OEMs and manufacturers face in today’s competitive landscape. We specialize in delivering high-quality, tailored solutions to meet your unique specifications. My approach combines state-of-the-art technology with meticulous attention to detail, ensuring each board is assembled with precision. Whether you require high-volume production or specialized low runs, our team is committed to exceeding your expectations. I take pride in communicating closely with clients, ensuring that every aspect of your project aligns with your business goals. Plus, our robust quality control processes mean you can rely on our assemblies to perform flawlessly in your applications. Don’t settle for anything less than the best when it comes to PCB Board Assembly. Let’s collaborate to transform your innovative ideas into reality, while maximizing efficiency and minimizing costs. Reach out today, and I’ll help you navigate the path to superior electronic solutions!

Pcb Board Assembly Is The Best in 2025

In 2025, the landscape of PCB board assembly is experiencing a transformative shift, driven by technological advancements and increasing demand for high-quality electronic components. As global procurement managers seek reliable partners, the focus lies on providers that not only deliver precision and efficiency but also adapt to evolving industry standards. Innovations such as automated assembly processes and enhanced quality control measures are ensuring that manufacturers can meet the rigorous demands of various sectors, including consumer electronics, automotive, and medical devices. One key trend is the rising integration of smart technologies in the assembly process. With capabilities such as AI-driven quality inspection and real-time production monitoring, businesses can achieve unprecedented levels of accuracy and speed. This not only reduces production timelines but also minimizes waste and lowers costs, providing significant value to procurement teams looking to maximize their budgets. Moreover, sustainability remains a critical concern; therefore, opting for environmentally friendly materials and processes is becoming a standard expectation among manufacturers, aligning with global initiatives for greener production methods. As the industry continues to evolve, aligning with a PCB board assembly provider that prioritizes innovation, quality, and sustainability will be essential for procurement professionals. The right partnership can not only streamline operations but also foster long-term growth and competitiveness in an increasingly interconnected global market. With 2025 at the forefront of these developments, the choice for high-quality PCB assembly has never been clearer.

Pcb Board Assembly Is The Best in 2025

| Assembly Type | Material Used | Lead Time (Weeks) | Testing Method | Certifications |

|---|---|---|---|---|

| Surface Mount Technology (SMT) | FR-4, Copper | 2-4 | Functional Testing | ISO 9001, IPC-A-610 |

| Through-Hole Technology (THT) | Glass-epoxy, Tin | 3-5 | In-Circuit Testing | RoHS Compliant |

| Mixed Technology | Polyimide, Silver | 4-6 | Automated Optical Inspection | UL Listed, IPC-7711 |

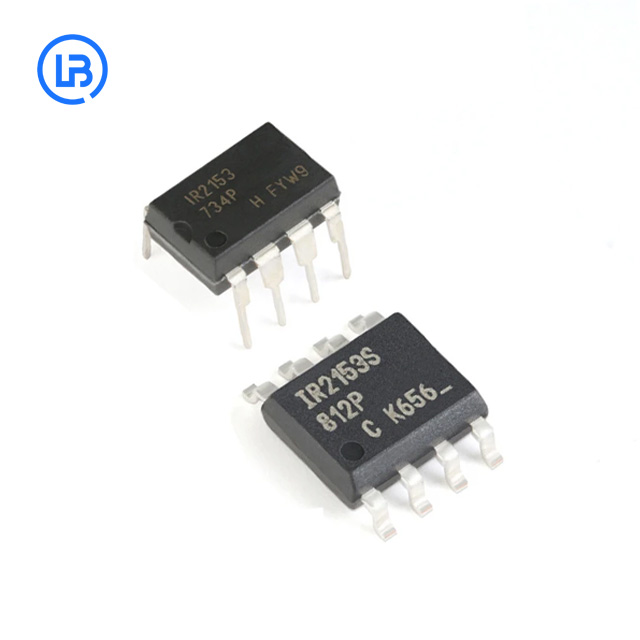

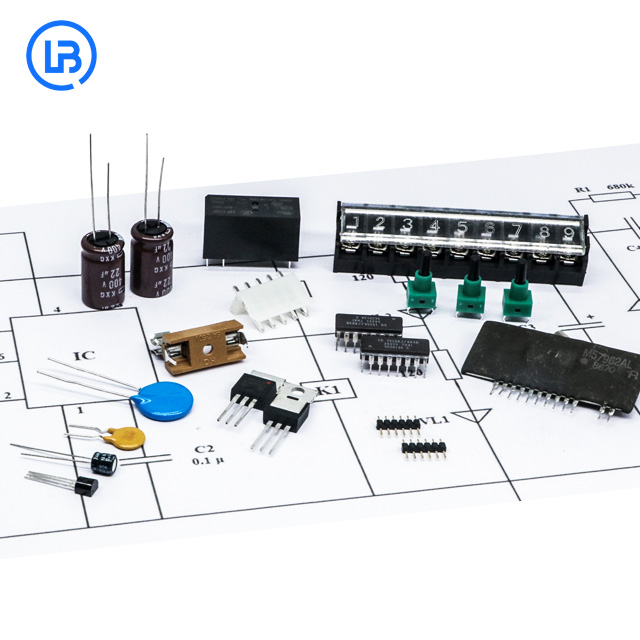

Related Products

Pcb Board Assembly Products Ahead of the Curve

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

WhatsApp

-

Top