High-Quality PCB Processing Services from a Trusted Manufacturer

When it comes to PCB processing, I believe that quality is paramount. That’s why I focus on delivering high-quality PCBs that meet the most stringent industry standards. As a manufacturer with years of experience, I understand the importance of precision and reliability in electronics. Whether you’re working on a small-scale project or a large production run, my services are tailored to your specific needs. I’m committed to using top-notch materials and innovative techniques to ensure that each PCB performs flawlessly. By choosing my PCB processing, you’re not just selecting a service; you’re investing in a partnership that values quality and efficiency. Let’s collaborate to bring your project to life with my precision-engineered boards, designed to exceed your expectations. Quality assurance throughout the manufacturing process is what I guarantee, ensuring your satisfaction at every step. Reach out today, and let’s get started on your next project!

Pcb Processing Guarantees Peak Performance From Concept to Delivery

In the fast-paced world of electronics, the efficacy of printed circuit board (PCB) processing is paramount to achieving peak performance from concept to delivery. Advanced PCB manufacturing techniques are essential for ensuring that every component functions seamlessly within the final product. By employing cutting-edge technology, strict quality control measures, and a skilled workforce, electronic technology providers can dramatically reduce lead times and enhance reliability, catering effectively to the dynamic needs of global buyers. The journey from concept to delivery involves meticulous planning and execution. It starts with working closely with clients to grasp their specific requirements, followed by prototyping and design validation to ensure optimal performance. Utilizing state-of-the-art equipment and materials, manufacturers optimize every stage of production, including etching, plating, and soldering. This precision not only improves product quality but also significantly boosts overall efficiency, resulting in quicker turnarounds and dependable outcomes that clients can trust. Moreover, robust logistics and supply chain management are crucial components that facilitate timely delivery of PCB products worldwide. By ensuring smooth transitions at every stage of the process, businesses can foster long-lasting partnerships with global buyers. Companies that prioritize reliable PCB processing help their clients meet stringent market demands, reduce development risks, and maintain competitiveness in a rapidly evolving landscape.

Pcb Processing Guarantees Peak Performance From Concept to Delivery

| Process Stage | Description | Turnaround Time | Quality Assurance | Technology Used |

|---|---|---|---|---|

| Design | Initial circuit layout and component placement. | 2-5 days | Design Rule Check (DRC) | CAD Software |

| Prototyping | Production of initial PCB prototypes. | 5-10 days | Visual Inspection | CNC Machines |

| Manufacturing | Mass production of PCBs based on approved designs. | 10-20 days | Automated Optical Inspection (AOI) | SMT and THT |

| Assembly | Attachment of components to the PCB. | 5-15 days | Functional Testing | Pick and Place Machines |

| Testing | Quality checks and performance validation. | 3-7 days | Burn-in Testing | Test Equipment |

| Delivery | Final package and shipping to client. | 2-4 days | Packaging Inspection | Logistics Management |

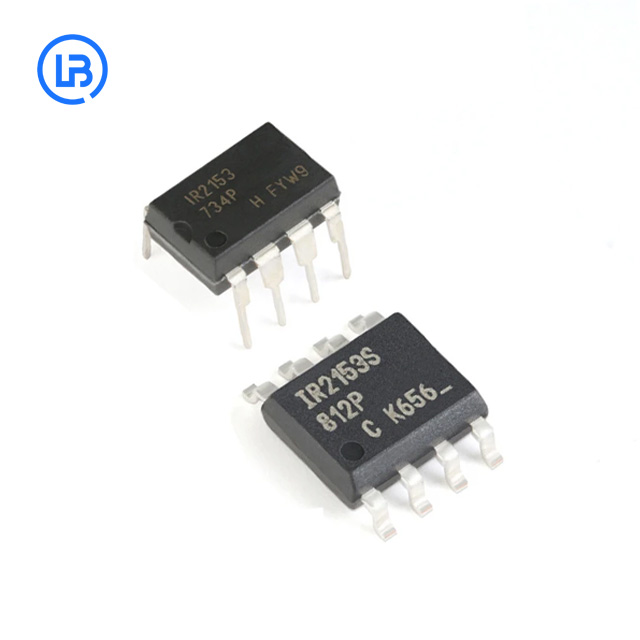

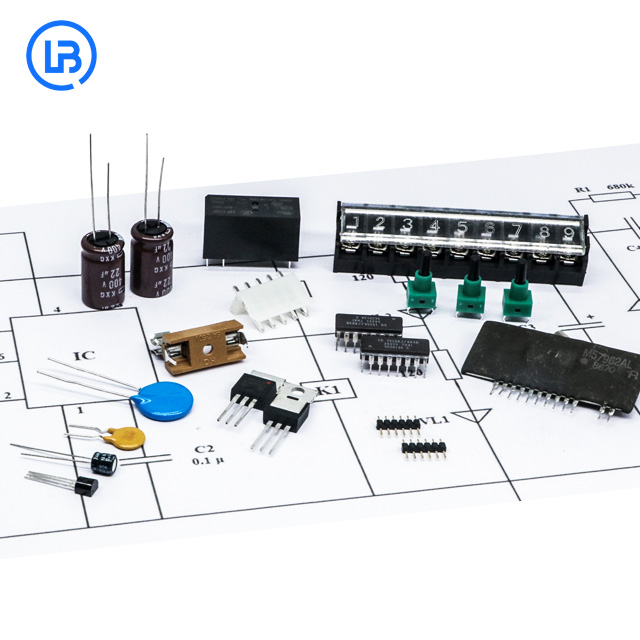

Related Products

Pcb Processing Industry Leaders Outperforms the Competition

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

WhatsApp

-

Top