Replacing Capacitors: Essential Guide for OEM Manufacturers & Users

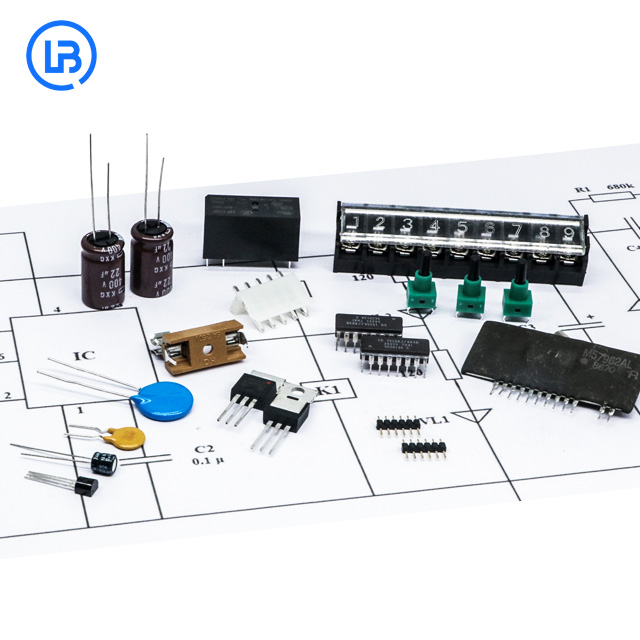

When it comes to replacing capacitors, I understand the challenges you face as OEM manufacturers. Finding reliable components that meet your specifications is crucial for maintaining quality and performance in your products. I’ve sourced high-grade capacitors that not only ensure durability but also enhance the efficiency of your electronic systems. With a wide variety of options available, I can help streamline your production processes and minimize downtime. I know how important it is to have a trusted supplier who understands the intricate needs of your industry. By partnering with us, you’re gaining access to premium capacitors designed specifically for your applications. Let’s work together to ensure your products maintain their competitive edge in the market. Whether it’s for high-volume production or specialized projects, I’m here to support your needs with the best solutions for replacing capacitors effectively and efficiently.

Replacing Capacitors Delivers Unmatched Quality Custom Solutions,

In the ever-evolving electronics industry, the quest for top-notch quality and customized solutions has never been more critical. One area that stands out in enhancing performance and reliability is capacitor replacement. By focusing on the intricate details of capacitor technology, manufacturers can significantly improve electronic device efficiency, extend operational lifetimes, and reduce maintenance costs. The process of replacing capacitors offers unparalleled flexibility for suppliers and manufacturers alike. Whether it’s for consumer electronics, automotive applications, or industrial machinery, tailoring capacitor specifications ensures that the end product meets exacting standards. Not only does this customization facilitate compatibility with existing systems, but it also allows for integration of advanced materials and technologies, driving innovation. Quality assurance remains paramount. Implementing rigorous testing protocols and adhering to global standards during replacement ensures that every component performs optimally. As global procurement teams seek reliable partners, the emphasis on quality custom solutions stands out as a core value, fostering long-term relationships and sustainable success in the competitive landscape.

Replacing Capacitors Delivers Unmatched Quality Custom Solutions

| Capacitor Type | Voltage Rating (V) | Capacitance (μF) | Temperature Range (°C) | Frequency Response (kHz) | Applications |

|---|---|---|---|---|---|

| Electrolytic | 50 | 10 | -40 to 85 | 1 | Power Supplies, Audio Equipment |

| Ceramic | 25 | 1 | -55 to 125 | 100 | RF Circuits, Oscillators |

| Tantalum | 35 | 4.7 | -55 to 125 | 10 | Consumer Electronics, Medical Devices |

| Film | 100 | 100 | -40 to 85 | 1 | Audio Equipment, Signal Processing |

| Aluminum Polymer | 10 | 47 | -55 to 105 | 100 | Power Circuits, High-Performance Applications |

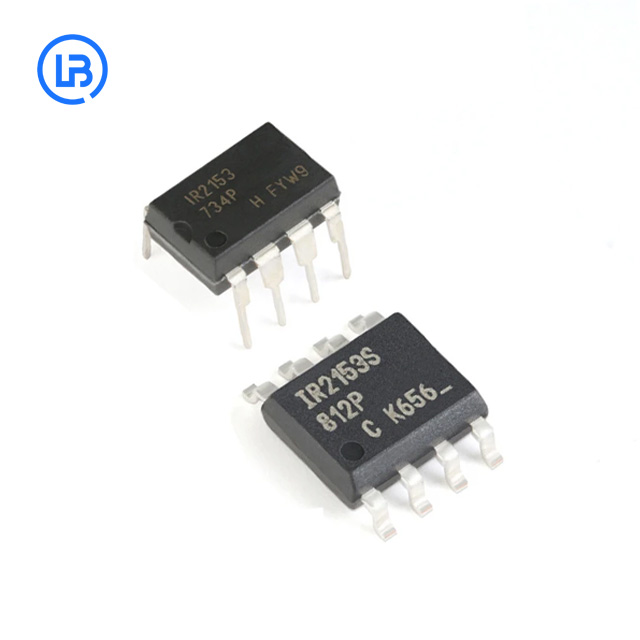

Related Products

Replacing Capacitors Ahead of the Curve Now Trending

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

WhatsApp

-

Top