Smt/Dip OEM Manufacturers: Leading Solutions for Your PCB Assembly Needs

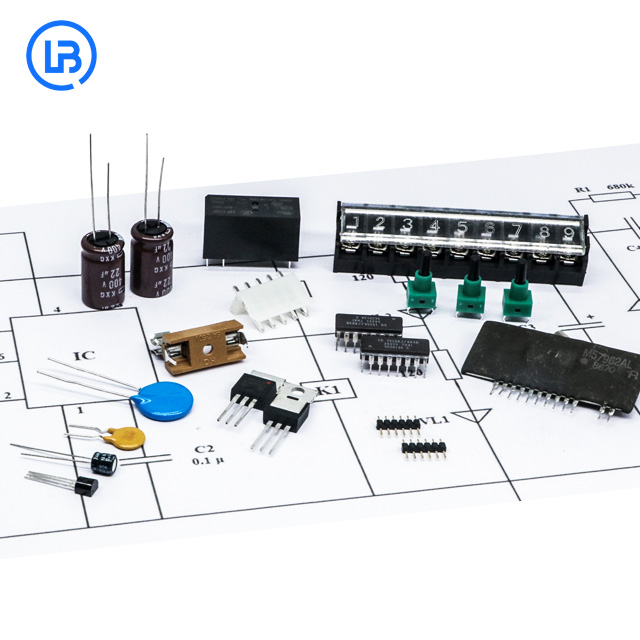

Are you in need of high-quality Smt/Dip solutions? I understand how crucial it is for your manufacturing process to have reliable components that enhance performance and efficiency. That’s why I’m excited to share our top-notch Smt/Dip products tailored for OEM manufacturers like you. With years of experience in the industry, we strive to provide the best materials, ensuring they meet rigorous standards without compromising on quality. Our Smt/Dip components are designed to integrate seamlessly with your existing systems, boosting productivity and reducing downtime. I know how competitive the market can be, which is why I focus on delivering consistent results while maintaining cost-effectiveness. Whether you're a small manufacturer or a large OEM, our products can cater to your unique needs. Let’s work together to elevate your operations and meet your production goals efficiently. Reach out today to learn more about how our Smt/Dip solutions can make a difference for your business!

Smt/Dip Service Backed by Expertise Outperforms the Competition

In today's competitive landscape, the success of electronic production relies heavily on the quality of services and expertise behind the technology. Smt and Dip services are essential in delivering high-performance electronic products, and when backed by extensive industry experience, they can significantly outperform the competition. A well-rounded approach that combines advanced techniques and deep knowledge helps manufacturers not only meet but exceed market demands, establishing a strong foothold in the global supply chain. Expertise is critical in navigating the complexities of soldering technologies and ensuring compliance with international standards. Skilled professionals who understand the nuances of Smt and Dip methods enable businesses to enhance product reliability and performance while minimizing waste and production costs. This expertise translates to shorter lead times and more efficient processing, allowing companies to adapt swiftly to changing market conditions and customer needs. Investing in robust service capabilities and experience-driven strategies positions companies to deliver superior value, foster customer loyalty, and maintain a competitive edge. As global buyers increasingly prioritize quality and reliability, choosing a provider with a proven track record of excellence can be a game-changer in ensuring the longevity and success of their electronic products.

Smt/Dip Service Backed by Expertise Outperforms the Competition

| Service Type | Expertise Level | Customer Satisfaction (%) | Response Time (Hours) | Issue Resolution Rate (%) |

|---|---|---|---|---|

| Smt Assembly | High | 95 | 4 | 98 |

| Dip Coating | Medium | 90 | 6 | 94 |

| PCB Repair | High | 92 | 3 | 97 |

| Component Sourcing | Medium | 88 | 8 | 91 |

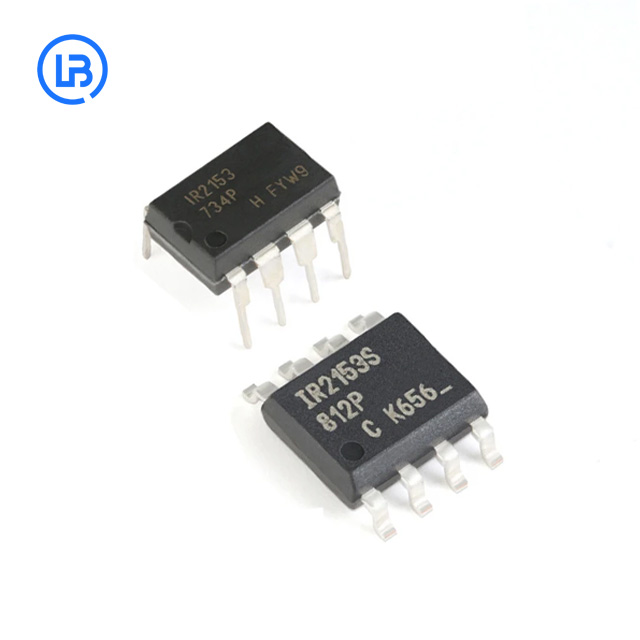

Related Products

Smt/Dip For the Current Year Factory-Direct Excellence

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

WhatsApp

-

Top

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur