Turbo Capacitor for OEM Manufacturers: Enhance Performance & Reliability

As a top supplier in the industry, I understand the critical role of turbo capacitors in various applications. Our turbo capacitors are designed specifically for OEM manufacturers needing reliable and efficient energy storage solutions. These components provide excellent performance, ensuring your systems run smoothly and efficiently. I know that as a manufacturer, you require products that not only meet strict specifications but also enhance your overall production quality. Our turbo capacitors deliver just that, with superior durability and a long lifespan, reducing the need for frequent replacements. Working closely with leading OEMs, we take pride in customizing our turbo capacitors to suit unique project requirements. Whether you’re in automotive, aerospace, or industrial sectors, our products can significantly contribute to your success. Let’s elevate your production capabilities together with our high-quality turbo capacitors, tailored for the demands of manufacturing excellence.

Turbo Capacitor Factory From Concept to Delivery

In the fast-evolving realm of electronic components, turbo capacitors have emerged as a critical innovation, bridging the gap between traditional power storage solutions and advanced energy systems. For global buyers seeking reliable suppliers, understanding the journey of turbo capacitors—from initial concept to final delivery—offers insights into quality, efficiency, and innovation. The development of turbo capacitors begins with meticulous research and design. Engineers analyze market needs and technological trends to create products that meet high-performance standards. They utilize state-of-the-art simulation tools to optimize the design, ensuring that each capacitor is not only efficient but also durable under varying conditions. This phase is crucial as it sets the foundation for manufacturing excellence. Once the prototypes meet strict performance benchmarks, they move onto the production floor, where precision manufacturing techniques come into play. Each capacitor is crafted using advanced materials and automated processes to guarantee consistency and reliability. After production, rigorous testing protocols ensure that every unit meets international standards before it reaches customers. A commitment to quality is maintained throughout the supply chain, ensuring that each delivery is prompt and accurate, empowering customers to achieve their project timelines. This seamless integration of design, manufacturing, and delivery positions turbo capacitors as a superior choice for diverse applications, from renewable energy systems to automotive technologies. As global procurement trends continue to evolve, choosing a partner that emphasizes innovation and reliability in turbo capacitor production becomes essential for sustained competitive advantage.

Turbo Capacitor Factory From Concept to Delivery

| Phase | Duration (Weeks) | Key Activities | Responsible Team | Completion Status |

|---|---|---|---|---|

| Concept Development | 4 | Market Research, Initial Design | R&D Team | Completed |

| Prototype Development | 6 | Build Prototype, Testing | Engineering Team | In Progress |

| Production Planning | 3 | Finalize Production Process, Setup | Operations Team | Pending |

| Production | 8 | Mass Production, Quality Control | Manufacturing Team | Upcoming |

| Delivery | 2 | Logistics, Shipping | Logistics Team | Pending |

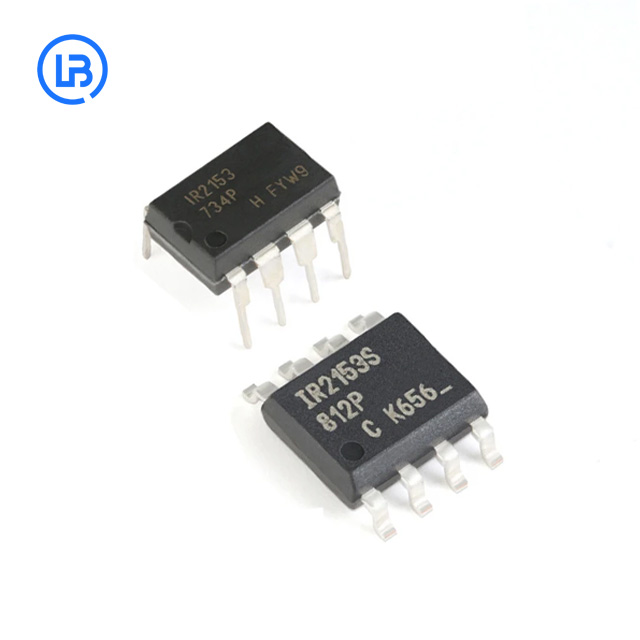

Related Products

Turbo Capacitor Leads the Global Market Custom Solutions,

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

WhatsApp

-

Top